The Strategic Advantage of Premium Shelled Walnuts in B2B Supply Chains

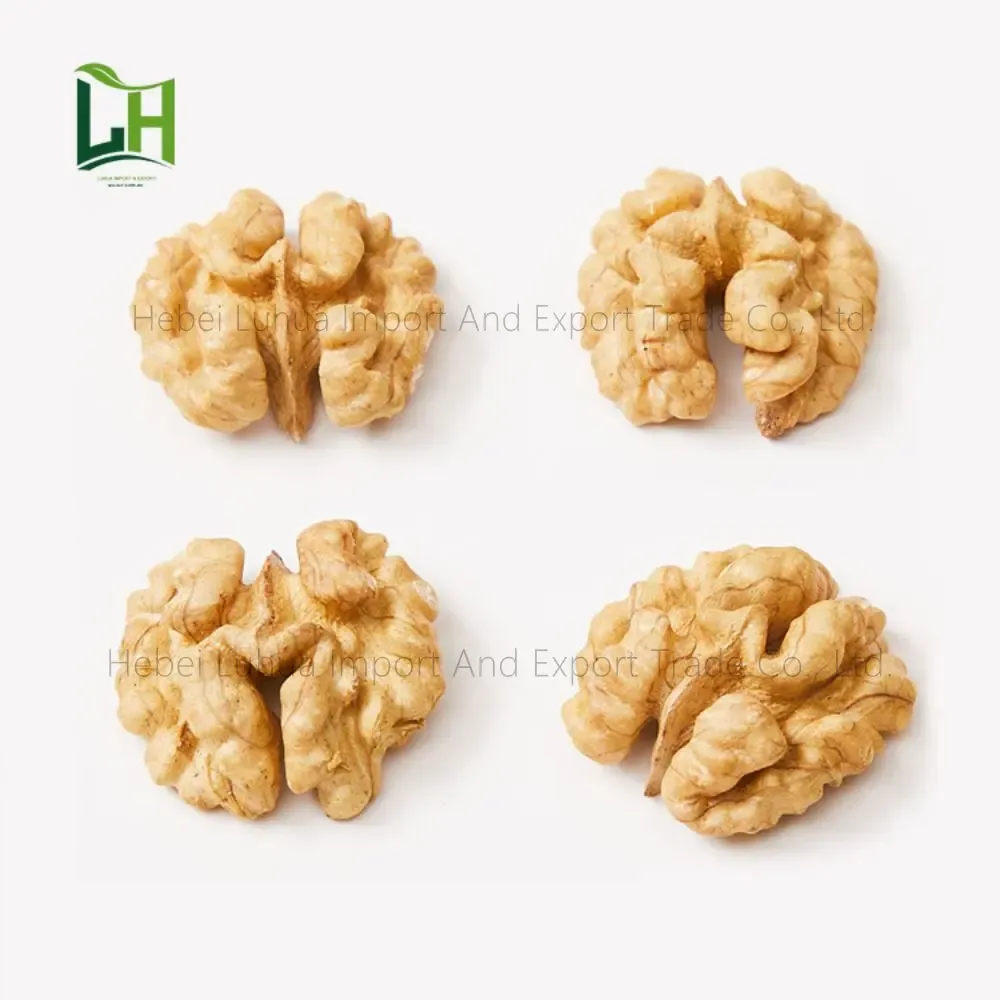

In the rapidly evolving global food industry, the demand for high-quality, sustainably sourced ingredients is paramount. For B2B stakeholders, understanding the intrinsic value and supply chain efficiencies of premium shelled walnuts is crucial. This comprehensive guide delves into the technical specifications, processing methodologies, and strategic advantages offered by leading suppliers, focusing on products like Yunnan Walnut Kernels Extra Light Halves (ELH) and Light Halves (LH).

The global market for walnuts is experiencing robust growth, driven by increasing consumer awareness of their health benefits, including omega-3 fatty acids, antioxidants, and essential minerals. This surge necessitates a reliable, consistent supply of processed kernels for various applications, from confectionery and bakery to health supplements and snack manufacturing. The shift towards ready-to-use ingredients underscores the importance of meticulously processed and graded kernels, ensuring both purity and convenience for industrial clients.

Current Industry Trends Driving Demand

- Health and Wellness Focus: Consumers increasingly prioritize ingredients with demonstrable health benefits, propelling walnuts into mainstream and specialized health food products.

- Convenience and Ready-to-Use: Manufacturers require ingredients that minimize preparation time and waste, making pre-shelled and graded kernels highly desirable.

- Sustainable Sourcing: Ethical and environmentally responsible sourcing practices are becoming non-negotiable for discerning B2B partners and their end consumers.

- Global Supply Chain Resilience: The need for diverse and reliable supply chains emphasizes partnerships with suppliers offering consistent quality and robust logistics.

The Meticulous Process Behind Premium Shelled Walnuts

The journey from raw shelled walnuts to a premium, ready-to-use ingredient involves a sophisticated and multi-stage process designed to ensure purity, quality, and consistency. Utilizing advanced technology combined with traditional craftsmanship, suppliers like Lu Hua Walnut transform raw materials into highly sought-after kernels. This intricate process ensures that each kernel meets stringent international standards.

Process Flow: From Harvest to Kernel

1. Sourcing & Pre-cleaning

Selection of premium Yunnan unshelled walnuts, followed by removal of debris, leaves, and preliminary washing.

2. Cracking & Shell Separation

Automated mechanical cracking, followed by advanced air separation and vibratory sifters to remove shell fragments from kernels.

3. Manual & Automated Sorting

Multi-stage sorting using color sorters and experienced human sorters to ensure kernel integrity, color uniformity, and removal of any remaining imperfections.

4. Drying & Moisture Control

Controlled drying processes to achieve optimal moisture content, critical for extended shelf life and preventing microbial growth.

5. Grading & Quality Control

Kernels are graded into categories like Extra Light Halves (ELH), Light Halves (LH), and Light Pieces (LHP) based on size, color, and integrity. Rigorous testing for microbiological purity and chemical residues.

6. Packaging & Storage

Vacuum-sealed or modified atmosphere packaging to preserve freshness, followed by storage in climate-controlled environments.

Product Materials: The foundation of superior shelled walnuts lies in the selection of high-quality raw materials. Yunnan walnuts are renowned for their thinner shells, higher kernel-to-shell ratio, and desirable flavor profile, making them an ideal choice for premium kernel production.

Testing Standards: Throughout the process, adherence to international testing standards is non-negotiable. This includes compliance with HACCP (Hazard Analysis Critical Control Point) principles, ISO 22000 for food safety management, and meeting specific requirements set by regulatory bodies such as the FDA (Food and Drug Administration) for imported food products. These standards ensure product safety, quality, and traceability from farm to factory.

Service Life: Properly processed and packaged shelled walnuts typically boast a shelf life of 12-24 months when stored under optimal conditions (cool, dry, dark environment, ideally refrigerated or frozen). This extended shelf life significantly benefits target industries by reducing waste and enabling flexible inventory management.

Advantages in Typical Application Scenarios

- Energy Saving & Efficiency: For industrial bakers, pre-shelled and graded walnuts eliminate the need for in-house shelling, reducing labor costs and energy consumption associated with raw material processing.

- Consistent Product Quality: Uniform kernel size and color ensure consistent end-product aesthetics and texture, crucial for branded food items.

- Enhanced Food Safety: Adherence to strict hygiene protocols and testing standards minimizes contamination risks, safeguarding consumer health and brand reputation.

- Supply Chain Optimization: Reliable supply of high-quality kernels streamlines procurement and inventory management for large-scale operations.

Technical Specifications and Quality Parameters

The quality of shelled walnuts is defined by a rigorous set of technical parameters, ensuring suitability for diverse industrial applications. Our Yunnan Walnut Kernels, available as Extra Light Halves (ELH) and Light Halves (LH), exemplify superior quality through meticulous grading and adherence to tight specifications. These specifications are critical for food manufacturers who require precise ingredient characteristics to maintain product consistency and meet regulatory compliance.

Product Specification Table: Yunnan Walnut Kernels

Understanding these parameters allows B2B buyers to select the precise grade of walnuts for their specific manufacturing needs. For instance, the low moisture content is vital for preventing spoilage and maintaining crispness in baked goods and snack mixes, while stringent microbiological testing guarantees safety for direct consumption or inclusion in sensitive food products.

Comparing Shelled vs. Unshelled Walnuts

For industrial procurement, the choice between shelled walnuts and unshelled walnuts is a critical economic and operational decision. While unshelled walnuts may initially appear to have a lower per-kilogram cost, the hidden expenses of shelling, sorting, and waste disposal can quickly outweigh these savings.

For high-volume operations where efficiency and cost predictability are paramount, sourcing premium shelled walnuts in bulk, such as a walnut 1 kg without shell pack, offers significant advantages.

Key Application Scenarios and Industry Benefits

The versatility of premium shelled walnuts makes them an indispensable ingredient across a spectrum of industries. Their rich nutritional profile, appealing texture, and mild, buttery flavor contribute significantly to product development and consumer satisfaction.

Target Industries and Specific Applications:

- Bakery & Confectionery: Ideal for cakes, cookies, bread, pastries, and chocolate bars. The consistent sizing of ELH and LH grades ensures uniform distribution and appealing presentation in these products.

- Snack Food Manufacturing: A staple in trail mixes, granola bars, roasted nut blends, and standalone healthy snack packs. The controlled moisture content prevents rancidity and maintains crunch.

- Dairy & Ice Cream: Used as inclusions in yogurt, ice cream, and other dairy desserts, adding texture and nutritional value.

- Health Food & Nutraceuticals: Incorporated into breakfast cereals, protein bars, and dietary supplements due to their high omega-3 content and antioxidant properties.

- Culinary & Foodservice: Utilized in salads, pestos, sauces, and main dishes by professional kitchens, offering both flavor and aesthetic appeal.

- Plant-Based Products: A key ingredient in plant-based meats and dairy alternatives, contributing to texture and nutritional enrichment.

Demonstrable Advantages in Use:

- Nutritional Enhancement: Walnuts are rich in α-linolenic acid (ALA), a plant-based omega-3 fatty acid, as well as protein, fiber, and various micronutrients. Incorporating them elevates the health profile of end products.

- Flavor and Texture Complexity: They provide a unique buttery, slightly earthy flavor and a satisfying crunch that enhances sensory appeal in a wide range of food items.

- Cost-Efficiency & Waste Reduction: By sourcing pre-processed kernels, manufacturers significantly reduce processing time, labor costs, and raw material waste, leading to a more streamlined and profitable operation.

- Extended Shelf-Life Integration: Due to optimal moisture control and packaging, our kernels integrate seamlessly into products, contributing to their overall stability and shelf life without compromising quality.

Authoritativeness: Certifications, Partnerships, and Quality Assurance

Establishing trust and authority is paramount in B2B transactions. Our commitment to providing premium shelled walnuts is underpinned by rigorous adherence to international standards, robust quality management systems, and a transparent supply chain. This dedication ensures not only product excellence but also operational integrity for our partners.

Certifications and Compliance:

- HACCP Certified: Our facilities operate under strict Hazard Analysis Critical Control Point (HACCP) principles, identifying and managing food safety risks at every stage of production.

- ISO 22000 Certified: We maintain ISO 22000 certification for Food Safety Management Systems, demonstrating a comprehensive approach to ensuring food safety from farm to fork.

- FDA Registered: Our products and processes meet the stringent requirements of the U.S. Food and Drug Administration, facilitating seamless import and distribution in North American markets.

- BRCGS Global Standard for Food Safety: Compliance with BRCGS standards reflects our commitment to best practices in manufacturing, hygiene, and product quality.

Decades of Experience and Partner Trust:

With over two decades of dedicated service in the nut industry, Lu Hua Walnut has cultivated extensive expertise in sourcing, processing, and supplying premium walnuts. Our long-standing relationships with global food manufacturers, major snack brands, and healthy food distributors attest to our reliability and commitment to partnership. We understand the critical nuances of industrial supply chains and offer tailored solutions to meet specific client needs.

Our internal test data, consistently verifying moisture content, microbial load, and peroxide values against international benchmarks, is readily available to our partners. This transparency, combined with independent third-party lab verification, reinforces our authoritative standing in the market.

Vendor Comparison and Customized Solutions

Selecting the right supplier for shelled walnuts is a strategic decision that impacts product quality, operational efficiency, and ultimately, profitability. Beyond basic pricing, B2B buyers must evaluate a vendor’s capability for consistent quality, supply chain robustness, and flexibility in meeting specific requirements.

Key Factors for Vendor Evaluation:

- Quality Consistency: Can the supplier consistently deliver the specified grades (ELH, LH) with minimal variation?

- Certifications & Food Safety: Are robust food safety management systems (HACCP, ISO, BRCGS) in place?

- Supply Chain Reliability: Does the vendor have a proven track record of on-time delivery and resilience against disruptions?

- Customization & Flexibility: Can they offer tailored solutions for specific particle sizes, moisture levels, or packaging?

- Traceability: Is there full transparency regarding the origin and processing of the walnuts?

Customized Solutions for B2B Partners:

Recognizing that every client has unique operational needs, we offer a range of customized solutions for shelled walnuts:

- Specific Grading Requirements: Beyond standard ELH/LH, we can tailor orders for specific percentages of halves vs. pieces, or more precise color definitions.

- Packaging Flexibility: Options for bulk packaging (e.g., 10kg, 25kg vacuum packs, 1000kg bulk bags) to smaller retail-ready formats, including various material choices for optimal shelf-life and handling.

- Processing Customizations: Offerings include raw, lightly toasted, or roasted walnuts, as well as specific particle sizes (e.g., small pieces, meal) for different manufacturing processes.

- Private Labeling: Support for co-branding or private label packaging solutions for distributor partners.

Application Case Studies: Realizing Value with Shelled Walnuts

The practical benefits of integrating high-quality shelled walnuts into industrial applications are best illustrated through real-world scenarios. Our partnerships demonstrate tangible improvements in product quality, efficiency, and market reach.

Case Study 1: Large-Scale Bakery Chain – Achieving Product Uniformity

A prominent national bakery chain faced challenges with inconsistent walnut quality and high labor costs associated with manual sorting of unshelled walnuts. They switched to our Yunnan Walnut Kernels ELH grade, specifically requesting 25kg vacuum-sealed bags.

- Challenge: Variable kernel size and color from previous suppliers led to inconsistent texture and visual appeal in their flagship walnut bread and pastries. Significant in-house labor was expended on quality checks and re-sorting.

- Solution: Implementation of Lu Hua’s ELH grade, known for its superior color and high percentage of intact halves, delivered in convenient bulk packaging.

- Results:

- 5% increase in product consistency score: As reported by internal QA, leading to better brand perception.

- 20% reduction in labor costs: Due to elimination of manual sorting and minimal quality control required upon receipt.

- Extended shelf life of finished goods: Attributed to the optimal moisture content and low peroxide value of the kernels.

Case Study 2: Health Food Manufacturer – Enhancing Nutritional Profile and Supply Reliability

A rapidly growing health food company, specializing in plant-based protein bars and trail mixes, required a consistent supply of walnuts that met strict nutritional and purity standards. They partnered with us for a continuous supply of Yunnan Walnut Kernels LH grade.

- Challenge: Previous suppliers struggled with consistent delivery volumes and often presented inconsistent microbiological test results, posing a risk to their ‘clean label’ products.

- Solution: A long-term supply agreement for our HACCP and ISO 22000 certified LH walnuts, with pre-agreed delivery schedules and comprehensive Certificates of Analysis (CoA) for each batch.

- Results:

- 100% on-time delivery rate: Ensuring uninterrupted production for new product launches.

- Zero rejections on microbiological tests: Bolstering product safety claims and brand integrity.

- Increased market share: Enabled by reliable supply and enhanced product quality, allowing for scaling up production confidently.

Trustworthiness: FAQs, Logistics, and Support

Building long-term B2B relationships hinges on transparency, clear communication, and dependable post-sales support. We prioritize these aspects to ensure our partners have complete confidence in their supply chain.

Frequently Asked Questions (FAQs):

- Q: What is the recommended storage for your shelled walnuts?

- A: To maintain optimal freshness and extend shelf life, store in a cool (preferably below 10°C / 50°F), dry, and dark environment. Refrigeration or freezing is highly recommended for long-term storage, in original sealed packaging.

- Q: What is the typical shelf life of your shelled walnuts?

- A: Our vacuum-packed or nitrogen-flushed walnuts have a typical shelf life of 12-24 months from the production date when stored correctly.

- Q: Are your products allergen-free?

- A: Walnuts are tree nuts and are considered a major allergen. Our facilities handle tree nuts. While we follow stringent cleaning protocols, cross-contamination cannot be entirely ruled out for highly sensitive individuals. Detailed allergen statements are available upon request.

- Q: What is your minimum order quantity (MOQ)?

- A: Our standard MOQ for industrial clients typically starts from 500 kg, though this can be flexible based on specific product grades and long-term partnership agreements. Please contact our sales team for details.

Lead Time and Fulfillment Details:

We operate with efficient logistics and a robust supply chain to ensure timely delivery. Standard lead times for stock items range from 7-14 business days for domestic shipments and 3-6 weeks for international orders, depending on destination and shipping method (sea freight, air freight). Custom orders may require additional lead time, which will be communicated clearly at the time of order confirmation. We provide comprehensive documentation for customs and shipping.

Warranty and Quality Commitment:

All our shelled walnuts are guaranteed to meet the agreed-upon specifications and international food safety standards at the point of delivery. In the unlikely event of any quality discrepancy, we commit to prompt investigation and resolution, including replacement or credit, in accordance with our transparent quality assurance policies. Our goal is 100% customer satisfaction through unwavering product excellence.

Customer Support and After-Sales Service:

Our dedicated B2B customer support team is available to assist with inquiries, order tracking, technical data requests, and any post-delivery concerns. Each client is assigned an account manager who acts as a single point of contact, ensuring personalized and efficient service. We believe in fostering long-term partnerships built on trust and mutual success.

Conclusion: Partnering for Excellence in Walnuts

The strategic procurement of high-quality, meticulously processed shelled walnuts is a critical determinant of success for food manufacturers and industrial clients. By understanding the intricate processing, adhering to stringent technical specifications, and leveraging reliable supply chains, businesses can ensure product excellence, operational efficiency, and enhanced consumer trust. Lu Hua Walnut is committed to being your trusted partner, delivering premium Yunnan Walnut Kernels that meet and exceed global industry standards.

References:

- Food and Agriculture Organization of the United Nations (FAO). (2023). Global production statistics for walnuts. Retrieved from FAOSTAT.

- USDA National Nutrient Database for Standard Reference. (2022). Walnuts, English, raw. Retrieved from Agricultural Research Service.

- International Organization for Standardization (ISO). (2018). ISO 22000:2018 Food safety management systems.

- BRCGS Global Standard for Food Safety. (2023). Issue 9.

- United States Food and Drug Administration (FDA). (2023). Guidance for Industry: HACCP Principles & Application Guidelines.

Hebei Luhua Import and Export Trade Co., Ltd.raisins is a large-scale walnut kernel processing factory, which has been focusing on the walnut kernel export industry since 1996 and established a foreign trade company in 2021.walnuts suppliers The factory covers an area of 50000 square meters, has a standardized production workshop, a BRC food safety certification enterprise, and has multiple professional production lines. xinjiang walnuts It can produce various specifications of walnut kernels and walnuts, with a daily output of up to 50 tons.organic cashews We can achieve faster delivery times and stable production, ensuring that you always have sufficient inventory to meet market demand.red dates|super blog