Industry Trends and Market Demand for Premium Walnuts

The global demand for high-quality nut kernels, particularly in the B2B sector, has seen a remarkable surge driven by evolving consumer preferences for healthy, plant-based, and convenient food options. Within this landscape, skinless walnuts represent a premium segment experiencing rapid growth. Food manufacturers, confectioners, bakeries, and nutraceutical companies are increasingly seeking these specialized kernels due to their enhanced aesthetic appeal, superior taste profile devoid of the common bitter notes from the pellicle, and improved versatility in various applications. This trend is further fueled by the rising awareness of walnuts’ nutritional benefits, including high omega-3 fatty acids, antioxidants, and essential minerals, making them a cornerstone ingredient for functional foods and health-oriented products.

The market is demanding not just walnuts, but specific, meticulously processed varieties that ensure consistency in quality, appearance, and flavor. This emphasis on refinement minimizes preparation time for industrial users and elevates the end-product experience for consumers. Factors such as ease of integration into complex formulations without imparting unwanted color or bitterness make skinless walnuts a preferred choice for premium offerings. Furthermore, global supply chain reliability and adherence to stringent food safety standards (e.g., HACCP, ISO 22000) are paramount considerations for B2B buyers, influencing their procurement decisions for high-value ingredients.

Precision Processing Flow for Superior Skinless Walnut Kernels

The production of premium skinless walnuts involves a sophisticated, multi-stage process designed to meticulously remove the bitter pellicle while preserving the kernel’s integrity, nutritional value, and characteristic mild flavor. Our manufacturing process, rooted in advanced food technology and strict quality control, ensures that each kernel meets the exacting standards of our B2B clientele.

Detailed Manufacturing Process:

1. Raw Material Sourcing & Inspection

Only premium-grade, in-shell walnuts, primarily from controlled orchards in China known for superior kernel quality, are selected. Rigorous inspection for size, moisture content, and absence of defects ensures optimal input material.

2. Cleaning & Sanitization

In-shell walnuts undergo multi-stage cleaning to remove dirt, debris, and foreign matter. This step utilizes high-pressure washing and sanitizing agents approved by food safety regulations, preparing them for cracking.

3. Automated Cracking & Shelling

State-of-the-art automated cracking machines are calibrated to minimize kernel breakage while efficiently separating the shell. This process is optimized to yield the highest percentage of whole halves and large pieces.

4. Initial Sorting & Separation

Post-cracking, kernels are passed through advanced optical sorting equipment and manual inspection lines to remove remaining shell fragments, imperfect kernels, and foreign materials.

5. Specialized Pellicle Removal (Peeling)

The peeled walnut process involves a proprietary, gentle technique to strip the thin, bitter pellicle from the kernel surface. This method avoids harsh chemicals and excessive heat, preserving the kernel’s natural flavor and texture. This is a critical step distinguishing our product.

6. Drying & Moisture Control

Post-peeling, kernels are carefully dried using controlled temperature and humidity parameters to achieve optimal moisture content (typically 4-6%). This significantly extends shelf life and prevents microbial growth, crucial for B2B storage and application.

7. Final Sorting, Grading & Packaging

Kernels undergo final optical and manual inspection, then are graded by size and quality (e.g., halves, pieces). They are then vacuum-packed or nitrogen-flushed into food-grade materials to maintain freshness and prevent oxidation, adhering to global shipping standards.

Quality Assurance & Testing Standards:

Our entire process is governed by a robust Quality Management System adhering to international standards such as ISO 22000 and HACCP. Each batch undergoes stringent laboratory testing for microbial counts, moisture content, peroxide value (indicator of freshness), and fatty acid profile. Compliance with FDA and EU food safety regulations is guaranteed. This meticulous control from raw material to packaged product ensures an extended service life and consistent quality for target industries including bakery, confectionery, dairy, snack manufacturing, and health food production, where precise ingredient specifications are critical.

Technical Specifications and Quality Parameters

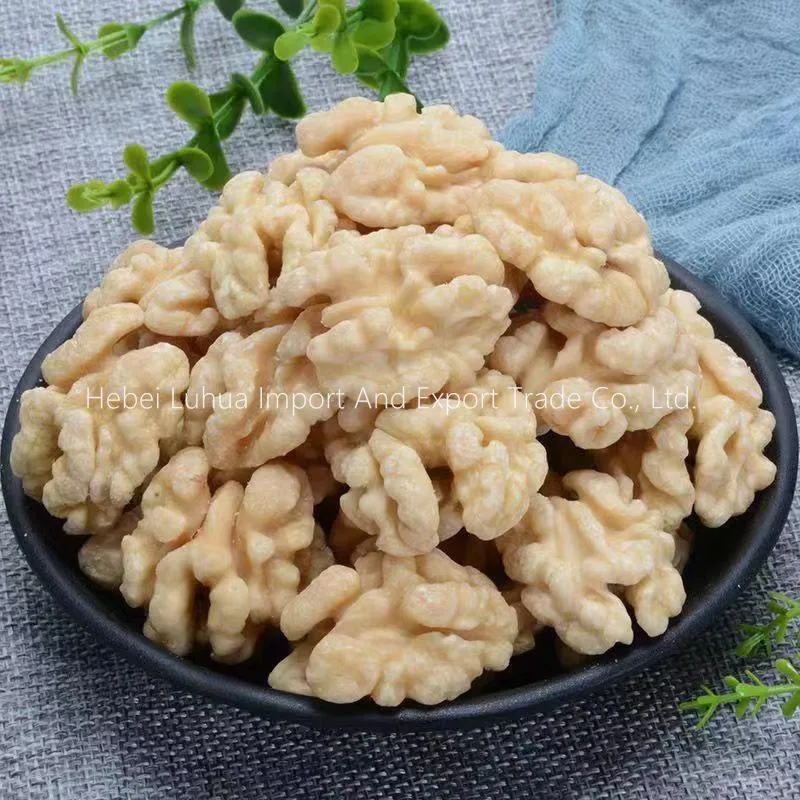

Our Chinese Professional Stripped And Drying Half Walnut Kernel product is engineered for superior performance and consistency in demanding B2B applications. Below are the key technical specifications and quality parameters that define our skinless walnuts, ensuring they meet the highest industry benchmarks.

Product Specification Table: Chinese Professional Stripped And Drying Half Walnut Kernel

| Parameter | Specification | Testing Method/Standard |

|---|---|---|

| Type | Half Walnut Kernel (Stripped & Dried) | Visual Inspection |

| Moisture Content | < 6.0% | AOAC 925.09 |

| Broken Kernel % (Small Pieces) | < 5.0% (for halves grade) | Manual Sieve Analysis |

| Foreign Matter | Absent | Visual Inspection & X-ray Detection |

| Damaged/Discolored Kernels | < 1.0% | Visual Inspection |

| Aflatoxin (B1, B2, G1, G2) | < 4 µg/kg (Total) | HPLC-FLD (EU Regulation) |

| Peroxide Value | < 5 meq O₂/kg | ISO 3976:2006 |

| Free Fatty Acids | < 1.0% (as Oleic Acid) | ISO 660:2009 |

| Microbiological Purity | E. coli, Salmonella, Listeria: Absent | ISO 6579, ISO 16649-1, ISO 11290-1 |

| Certifications | ISO 22000, HACCP, Kosher, Halal | Audited & Certified |

These specifications ensure that our skinless walnuts deliver consistent quality, extended shelf life, and optimal performance in diverse food manufacturing environments. Our commitment to these standards minimizes processing waste and maximizes yield for our industrial partners.

Application Scenarios and Technical Advantages

The unique characteristics of skinless walnuts make them indispensable across a spectrum of B2B applications where both nutritional value and sensory experience are paramount. Their refined profile offers distinct technical advantages over conventional walnuts.

Typical Application Scenarios:

- Premium Confectionery: Ideal for chocolate bars, pralines, truffles, and gourmet candy where the absence of bitterness and light color enhance the overall flavor and visual appeal.

- Fine Bakery Products: Used in high-end cakes, pastries, cookies, and artisanal breads. The smooth texture and mild flavor integrate seamlessly without overpowering other ingredients.

- Dairy & Alternative Dairy: Incorporated into yogurts, ice creams, nut milks, and plant-based desserts for added texture, nutritional boost, and a clean flavor profile.

- Nutraceuticals & Health Bars: Formulations for energy bars, protein shakes, and dietary supplements benefit from the superior nutritional density and palatable nature of peeled walnuts.

- Gourmet Snacking & Trail Mixes: Preferred for standalone snacking or inclusion in premium trail mixes due to their milder taste and attractive appearance, driving consumer preference.

- Salad Toppings & Savory Dishes: Restaurants and food service providers use them for upscale salads, garnishes, and as an ingredient in certain savory dishes where the bitterness of the pellicle would be undesirable.

Key Technical Advantages:

- Elimination of Bitterness: The primary advantage is the removal of the tannic pellicle, which is responsible for the characteristic bitterness in raw walnuts. This results in a cleaner, milder, and sweeter flavor profile, enhancing palatability.

- Superior Aesthetics: The lighter, uniform cream color of stripped kernels is highly desirable for applications where visual appeal is crucial, preventing discoloration in light-colored products.

- Enhanced Ingredient Compatibility: With their neutral flavor, these walnuts blend seamlessly with other ingredients, allowing the nuanced flavors of the overall product to shine through without interference.

- Extended Shelf Life: Our controlled drying process achieves optimal moisture content, which, combined with protective packaging, significantly retards oxidative rancidity and microbial spoilage, ensuring longer freshness for industrial inventory.

- Reduced Processing Time: As they are pre-peeled and sorted, they eliminate the need for in-house preparation by manufacturers, streamlining production lines and reducing labor costs.

- Consistent Quality: Rigorous quality control measures throughout the process guarantee a consistent product in terms of size, color, moisture, and flavor, critical for large-scale production.

Vendor Comparison: Why Choose Our Skinless Walnuts

Selecting the right supplier for high-volume, high-quality ingredients like skinless walnuts is a strategic decision for B2B entities. Our commitment to excellence in product quality, process integrity, and customer service positions us as a leading partner in the industry. Below is a comparative analysis highlighting our distinguishing factors against typical market offerings, especially considering the peeled walnuts price and overall value proposition.

Product Comparison Table: Leading Supplier vs. Others

| Feature/Criterion | Our Company (Lu Hua Walnut) | Typical Supplier A (Commodity Grade) | Typical Supplier B (Mid-Tier) |

|---|---|---|---|

| Pellicle Removal Technique | Proprietary gentle mechanical and blanching, no harsh chemicals. | Often chemical baths or rudimentary abrasion, inconsistent. | Blanching with less precise control; may use some additives. |

| Final Kernel Color | Consistent light cream/white, minimal discoloration. | Variable, often yellowish or with residual dark spots. | Mostly light, but some inconsistency can occur. |

| Taste Profile | Mild, sweet, buttery, absolutely no bitterness. | Often retains some bitterness, sometimes chemical aftertaste. | Mild, but may have slight tannic notes. |

| Moisture Content Control | Precisely controlled (4-6%), optimized for shelf life. | Less consistent, higher variability, impacting freshness. | Generally good, but may lack precision for long-term storage. |

| Certifications | ISO 22000, HACCP, Kosher, Halal, FDA-compliant. | Basic food safety only, or regional certifications. | Some international certs, but possibly not comprehensive. |

| Minimum Order Quantity (MOQ) | Flexible, tailored to B2B needs. | High, often inflexible. | Moderate, some flexibility. |

| Customization Options | Extensive (size, packaging, roasting, specific quality grades). | Minimal or none. | Limited. |

| Technical Support & Partnership | Dedicated B2B support, R&D collaboration. | Transactional, limited post-sale support. | Basic customer service. |

| Peel Walnut Price Point | Premium, justified by superior quality and processing. | Lower, reflecting inconsistent quality and processing. | Mid-range, with varying quality. |

While the initial peeled walnuts price from a premium supplier like ours might appear higher than commodity-grade options, the total cost of ownership is often lower. This is due to reduced waste, extended shelf life, enhanced product consistency, and the elimination of in-house quality control issues, which collectively contribute to higher efficiency and better end-product quality for our clients. Our investment in advanced peeling technology and stringent quality protocols ensures a consistent, high-value ingredient.

Customized Solutions and Application Case Studies

Recognizing that B2B clients often have unique requirements, we specialize in providing tailored solutions for our skinless walnuts. Our flexibility extends beyond standard product offerings to encompass specific processing, packaging, and delivery protocols, ensuring seamless integration into diverse manufacturing environments.

Customization Options:

- Granulation & Sizing: Beyond halves and large pieces, we can custom-process kernels into various granulations (e.g., small pieces, meal, flour) to meet specific recipe requirements.

- Roasting & Flavoring: Offering custom roasting levels (light, medium, dark) or even specialized flavor profiles (e.g., lightly salted, honey-glazed) for ready-to-use applications.

- Packaging Formats: Flexible packaging solutions ranging from bulk bags (e.g., 10kg, 25kg vacuum-sealed) to smaller, retail-ready pouches, all designed to maintain freshness and integrity.

- Specific Quality Grades: Tailoring quality parameters such as color, broken percentage, or fatty acid profiles to align with unique product specifications and target market demands.

- Logistics & Delivery: Coordinated supply chain management, including just-in-time delivery options and customized shipping schedules, to optimize client inventory and production flow.

Application Case Study: Enhancing a Gourmet Chocolate Line

Client Profile: A prominent European gourmet chocolate manufacturer, specializing in high-end, artisanal chocolate bars and confections.

Challenge: The client sought to launch a new line of premium walnut-infused chocolates. Their existing supplier’s standard walnuts presented issues: inconsistent color (dark spots detracted from visual appeal), occasional bitterness from the pellicle, and variable piece sizes, leading to increased internal sorting and quality control costs. The inconsistent “peel walnut” quality impacted both taste and aesthetics.

Our Solution: We partnered with the client to provide our specialized skinless walnuts. We offered a custom-graded kernel, ensuring uniform halves with a pristine, light cream color and absolutely no residual pellicle. Our team worked to establish a specific moisture content and packaging protocol to ensure optimal freshness upon arrival, even with long transit times.

Results & Impact:

- Superior Product Quality: The new chocolate line received rave reviews for its clean, balanced flavor and elegant appearance, directly attributed to the premium kernels.

- Reduced Operational Costs: The client significantly reduced their in-house quality control and sorting efforts, leading to a 15% reduction in labor costs associated with ingredient preparation.

- Enhanced Brand Reputation: The consistent high quality of the ingredient reinforced the client’s reputation as a purveyor of premium chocolates, leading to increased market share in the gourmet segment.

- Optimized Shelf Life: Our precise moisture control and packaging extended the shelf life of the ingredient, reducing spoilage and inventory management challenges for the client.

This case exemplifies how our commitment to specialized processing and client partnership provides tangible benefits that extend beyond mere ingredient supply, contributing directly to our clients’ success and profitability.

Trustworthiness and Client Support ( Assurance)

Our dedication to transparency, reliability, and unparalleled customer service underpins every aspect of our operations. We believe that building long-term B2B partnerships is founded on absolute trustworthiness, supported by robust internal processes and clear commitments.

Frequently Asked Questions (FAQ) for B2B Clients:

A: When stored properly in a cool, dry place (ideally refrigerated or frozen) and in original sealed packaging, our skinless walnuts maintain optimum quality for 12-18 months. Our low moisture content and protective packaging significantly extend freshness.

Q: What are your minimum order quantities (MOQs)?

A: MOQs are flexible and can be discussed based on product type, customization requirements, and order frequency. We aim to accommodate both small-batch specialty manufacturers and large-scale industrial clients. Please contact our sales team for detailed information.

Q: Do you provide product certifications and lab analysis reports?

A: Absolutely. Each shipment is accompanied by a Certificate of Analysis (COA) detailing compliance with all specified parameters. We hold ISO 22000, HACCP, Kosher, and Halal certifications, and adhere to FDA and EU food safety standards.

Q: Can you accommodate specific packaging requirements?

A: Yes, we offer various packaging solutions, including vacuum-sealed bags, nitrogen-flushed container111s, and custom weights, designed to meet your logistics and production needs.

Lead Time & Fulfillment Details:

Our streamlined production and robust supply chain allow for efficient order fulfillment. Standard lead times typically range from 10-20 business days from order confirmation, depending on the volume, customization, and destination. For urgent requests or large-scale projects, we work closely with clients to establish realistic and optimized delivery schedules. Our logistics team coordinates with reputable shipping partners to ensure timely and secure global delivery.

Warranty Commitments & Quality Assurance:

We stand by the superior quality of our skinless walnuts. All products are guaranteed to meet or exceed the specifications outlined in our COA and agreed-upon contracts. In the rare event of a quality discrepancy, we commit to prompt investigation and resolution, offering replacement or credit as appropriate. Our comprehensive quality management system (QMS) is designed to proactively prevent issues and ensure client satisfaction.

Dedicated Customer Support:

Our B2B clients benefit from dedicated account management and technical support teams. From initial inquiry to post-delivery assistance, our experts are available to provide guidance on product selection, application optimization, storage, and any technical queries. We aim to be a seamless extension of your procurement and R&D departments.

Contact Information:

For sales inquiries, technical support, or to discuss custom solutions, please visit our website at www.luhuawalnut.com or reach out to our sales team directly via email or phone as listed on our contact page.

References

- International Organization for Standardization (ISO). (2020). ISO 22000:2018 Food safety management systems.

- Food and Drug Administration (FDA). (2023). Food Safety Modernization Act (FSMA).

- Hazard Analysis and Critical Control Points (HACCP) principles. (Codex Alimentarius).

- USDA National Nutrient Database for Standard Reference. (2022). Walnuts, English.

- Ros, E. (2010). Health benefits of nut consumption. Nutrients, 2(7), 652-682.

- Food and Agriculture Organization of the United Nations (FAO). (2023). Agricultural Production Statistics.

Hebei Luhua Import and Export Trade Co., Ltd.raisins is a large-scale walnut kernel processing factory, which has been focusing on the walnut kernel export industry since 1996 and established a foreign trade company in 2021.walnuts suppliers The factory covers an area of 50000 square meters, has a standardized production workshop, a BRC food safety certification enterprise, and has multiple professional production lines. xinjiang walnuts It can produce various specifications of walnut kernels and walnuts, with a daily output of up to 50 tons.organic cashews We can achieve faster delivery times and stable production, ensuring that you always have sufficient inventory to meet market demand.red dates|super blog