Understanding Shelled Walnuts: Industry Trends and Technical Parameters

The global market for nuts, particularly those with significant nutritional value, has seen consistent growth. Within this sector, shelled walnuts are highly sought after for their versatility in culinary applications, nutritional density, and convenience. Consumer demand for ready-to-use ingredients, coupled with increasing awareness of health benefits, fuels this trend. The shift from traditional `unshelled walnuts` to pre-processed kernels streamlines supply chains and reduces preparation time for industrial users and consumers alike.

Emerging trends include a greater focus on sustainable sourcing, organic certifications, and traceability from farm to table. B2B purchasers are increasingly scrutinizing not only the quality and grade but also the ethical and environmental practices of suppliers. For instance, the demand for high-quality shelled walnuts, such as Yunnan Walnut Kernels Extra Light Halves (ELH) and Light Halves (LH), reflects a preference for premium products that offer superior aesthetic appeal and taste profiles for high-end confectionery, bakery, and health food markets.

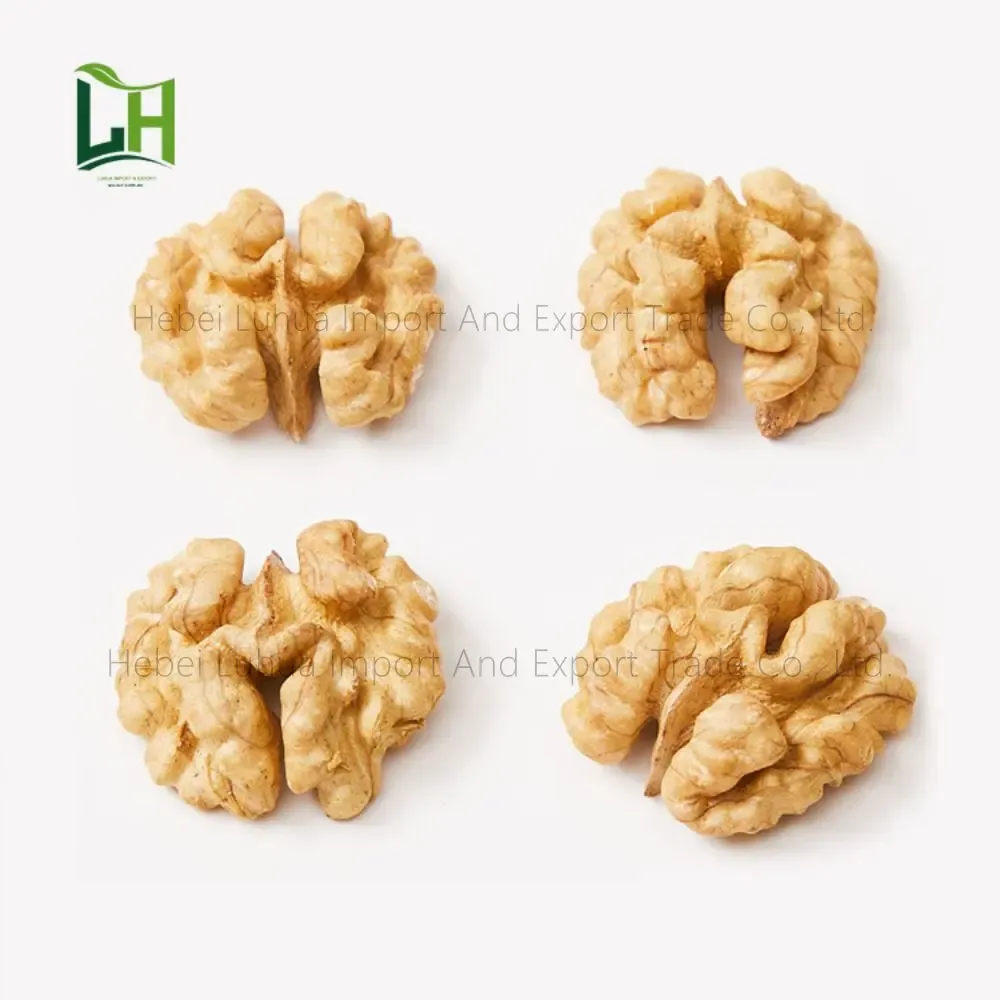

Figure 1: Premium Extra Light Halves of Shelled Walnuts

Key Technical Parameters for Shelled Walnut Kernels

For B2B applications, the technical specifications of shelled walnuts are paramount. These parameters dictate their suitability for various industrial processes and ensure consistent product quality in end applications. Critical factors include kernel integrity, moisture content, color classification, and freedom from defects. These are often aligned with international standards to ensure interchangeability and quality assurance across global supply chains.

| Parameter | Yunnan Walnut Kernels ELH (Extra Light Halves) | Yunnan Walnut Kernels LH (Light Halves) | Testing Standard |

|---|---|---|---|

| Color Grade | Extra Light | Light | USDA Standard for Walnuts |

| Moisture Content | Max 6.0% | Max 6.0% | AOAC 925.09 |

| Halves Ratio | Min 80% | Min 80% | Visual Inspection |

| Broken Kernels | Max 5% | Max 5% | Visual Inspection |

| Foreign Matter | Absent | Absent | FDA BAM Chapter 10 |

| Peroxide Value | Max 5 meq O2/kg | Max 5 meq O2/kg | ISO 3960 |

| Aflatoxins | Max 4 ppb (B1) / 10 ppb (Total) | Max 4 ppb (B1) / 10 ppb (Total) | EU 1881/2006, FDA Guidance |

Detailed Manufacturing Process of Shelled Walnuts

The production of high-quality shelled walnuts involves a meticulous process, from raw material procurement to final packaging, ensuring optimal product integrity and safety. This sophisticated process, incorporating elements of material handling, mechanical processing, and stringent quality control, is crucial for meeting the demanding specifications of B2B clients, whether they require large quantities like `walnut 1 kg without shell` packs or bulk shipments for industrial use.

Our process ensures that raw `unshelled walnuts` are transformed into premium kernels with minimal damage and maximum freshness, adhering to international food safety and quality standards like ISO 22000 and HACCP principles.

Process Flow Overview:

Step 1: Sourcing & Initial Inspection

Raw `unshelled walnuts` are meticulously sourced from designated farms, primarily in Yunnan. Initial inspection involves assessing external quality, size uniformity, and moisture content of the in-shell nuts. Only premium raw materials meeting our stringent criteria are accepted for processing.

Step 2: Washing & Drying

The `unshelled walnuts` undergo a thorough washing process to remove any surface impurities. This is followed by controlled drying to achieve optimal moisture levels (typically 8-10%) suitable for efficient cracking and to prevent mold growth, crucial for extended service life of the kernels.

Step 3: Cracking & Shell Separation

Advanced mechanical cracking machines are utilized, carefully calibrated to minimize kernel damage. Following cracking, a multi-stage separation process using air currents and vibrating screens efficiently removes shell fragments from the kernels. This stage is critical for achieving high yields of whole halves.

Step 4: Manual Sorting & Grading

Skilled personnel meticulously hand-sort the kernels to remove any remaining shell particles, discolored nuts, or imperfect pieces. This is followed by grading based on size (halves, quarters, pieces) and color (Extra Light, Light, Light Amber), aligning with USDA and ISO standards. This human intervention ensures superior final product quality.

Step 5: Quality Control & Metal Detection

Each batch undergoes rigorous quality control checks, including moisture content analysis (AOAC 925.09), peroxide value assessment (ISO 3960) to monitor freshness, and microbiological testing. High-sensitivity metal detectors are used to ensure no metallic foreign objects are present, adhering to ANSI food safety protocols.

Step 6: Packaging & Storage

The final shelled walnuts are packed in food-grade, airtight packaging, often vacuum-sealed or nitrogen-flushed, to preserve freshness and extend shelf life. They are then stored in climate-controlled warehouses, typically at 0-4°C and 60-70% RH, safeguarding their quality until dispatch.

Figure 2: Manual Sorting for Optimal Shelled Walnut Quality

This comprehensive process ensures that our Yunnan Walnut Kernels Extra Light Halves and Light Halves maintain their structural integrity, nutritional profile, and sensory attributes, providing a reliable ingredient for target industries such as confectioneries, bakeries, healthy snack producers, and fine dining establishments. The advantage in typical application scenarios includes not only superior product aesthetics and taste but also enhanced shelf stability due to rigorous processing and packaging, contributing to energy saving in downstream processes by eliminating the need for further sorting or cleaning.

Application Scenarios and Technical Advantages

The versatility and nutritional benefits of shelled walnuts make them an indispensable ingredient across a multitude of industries. From enhancing texture and flavor to boosting nutritional content, their applications are diverse and growing, particularly for high-quality formats like the Yunnan Walnut Kernels Extra Light Halves (ELH) and Light Halves (LH).

Primary Application Scenarios:

- Bakery and Confectionery: Utilized in cakes, cookies, bread, pastries, and chocolates. The extra light halves provide a premium visual appeal and delicate crunch. Their stable lipid profile helps maintain freshness in baked goods.

- Dairy & Ice Cream: As inclusions in yogurts, ice creams, and desserts, offering textural contrast and a rich, nutty flavor.

- Health Foods & Snacks: Key component in trail mixes, granola bars, and specialized health food products due to their high omega-3 fatty acid content, antioxidants, and protein. Convenience in packaging such as a `walnut 1 kg without shell` pack is highly valued here.

- Culinary & Food Service: Used in salads, pesto, pasta dishes, and as a garnish in gourmet cuisine. The consistent size and color of ELH/LH grades ensure uniformity in professional kitchens.

- Nutraceuticals: Processed into walnut oil, flour, or extracts for use in dietary supplements, leveraging their brain-health benefits and anti-inflammatory properties.

Figure 3: Shelled Walnuts in Bakery Applications

Technical Advantages of Premium Shelled Walnuts:

- Superior Quality & Consistency: Rigorous sorting and grading ensure uniform size, color, and integrity, which are critical for automated production lines in industrial settings. This minimizes waste and optimizes process efficiency.

- Enhanced Shelf Stability: Advanced drying and packaging techniques (e.g., vacuum sealing, nitrogen flushing) significantly reduce oxidation and moisture absorption, extending the product’s freshness and flavor profile, critical for avoiding spoilage costs.

- Food Safety & Compliance: Adherence to international standards (e.g., ISO, HACCP, FDA) and comprehensive testing for contaminants (aflatoxins, heavy metals) ensures product safety and facilitates global market access.

- Nutritional Value Preservation: Gentle processing methods help retain the delicate omega-3 fatty acids, antioxidants, vitamins, and minerals, providing maximum health benefits to end consumers.

- Cost Efficiency for B2B: Purchasing pre-processed shelled walnuts eliminates the need for de-shelling, sorting, and cleaning at the client’s facility, translating into significant labor, equipment, and energy cost savings. This is particularly advantageous when dealing with bulk orders or high-volume production.

These advantages underscore why B2B decision-makers prioritize suppliers who can consistently deliver high-grade shelled walnuts that meet exacting technical and quality requirements, directly impacting their product quality and operational efficiency.

Vendor Comparison and Customized Solutions

Selecting the right supplier for shelled walnuts is a strategic decision for B2B enterprises. Factors beyond price, such as product quality, consistency, certifications, logistical capabilities, and the ability to provide customized solutions, significantly influence the long-term value of a partnership. Our commitment to expertise and authoritativeness is reflected in our robust operational framework and certifications.

Key Considerations for Vendor Comparison:

- Quality Assurance & Certifications: Look for suppliers with ISO 22000, HACCP, BRCGS, or equivalent certifications, demonstrating adherence to international food safety management systems. Our facilities are regularly audited to maintain these rigorous standards.

- Origin and Traceability: Transparency regarding the origin of `unshelled walnuts` and a robust traceability system from farm to final product. This ensures ethical sourcing and quality control at every stage.

- Processing Capabilities: Advanced processing technology that minimizes damage, optimizes sorting, and ensures consistent quality (e.g., minimal broken pieces, accurate color grading).

- Packaging Expertise: Ability to provide packaging solutions that extend shelf life and suit diverse logistical requirements, from bulk container111s to specific formats like `walnut 1 kg without shell` retail packs.

- Customer Service & Support: Responsiveness, flexibility, and a dedicated account management team that understands specific B2B needs.

Our Customized Solutions:

Recognizing that each B2B client has unique requirements, we offer tailored solutions to integrate our Yunnan Walnut Kernels seamlessly into your production processes. Our expertise extends to:

- Specific Grading & Sizing: Beyond standard ELH/LH, we can customize grades based on your desired halves-to-pieces ratio or specific kernel sizes for particular applications.

- Tailored Packaging: From industrial bulk bags (e.g., 25kg, 1000kg totes) to smaller, specific weight configurations (e.g., `walnut 1 kg without shell`), we offer flexible packaging options with inert gas flushing or vacuum sealing for optimized shelf life and handling.

- Private Labeling: For clients seeking to white-label products, we provide private labeling services, adhering to your branding and packaging specifications.

- Logistical Integration: Working closely with your supply chain team, we can optimize delivery schedules, warehousing, and transportation methods to ensure just-in-time delivery and reduce inventory costs.

- Co-development & R&D Support: Our technical team can collaborate on new product development, offering insights into walnut kernel applications, stability, and sensory profiles to meet emerging market demands.

Figure 4: Advanced Packaging for Preserving Shelled Walnuts

Our extensive experience and dedication to quality have enabled us to forge long-standing partnerships with leading food manufacturers globally, establishing our authority in the premium shelled walnuts market.

Application Case Studies and Trustworthiness

Our commitment to delivering superior Yunnan Walnut Kernels is substantiated by successful application case studies and a transparent approach to trustworthiness. We believe in demonstrating our value through real-world examples and clear commitments to our clients.

Case Study 1: Large-Scale Bakery Chain Integration

A prominent international bakery chain sought to upgrade the quality of nuts used in their premium bread and pastry lines. They faced challenges with inconsistent sizing, high breakage rates, and variable color in their previous supplier’s shelled walnuts. Upon switching to our Yunnan Walnut Kernels ELH, they reported a 15% reduction in production line waste due to the consistent halves ratio and minimal broken pieces. The superior light color also enhanced the visual appeal of their finished products, leading to a 5% increase in consumer preference feedback. Our ability to provide a consistent `walnut 1 kg without shell` bulk format also streamlined their inventory management.

Figure 5: High-Quality Walnuts for Industrial Use

Case Study 2: Health Snack Manufacturer Partnership

A leading producer of high-protein, organic snack bars required a consistent supply of premium Light Halves for their product line. Their primary concern was ensuring the highest nutritional integrity and extended shelf life for their perishable ingredients. Our vacuum-packed Yunnan Walnut Kernels LH, with a guaranteed moisture content of below 6% and low peroxide value (tested via ISO 3960), met their stringent requirements. The client noted a 20% improvement in their product’s “best by” date and reported zero instances of rancidity complaints, directly attributing this to the superior quality and packaging of our `walnut 1 kg without shell` kernels.

Ensuring Trustworthiness:

Figure 6: Quality Assurance for Shelled Walnuts

- FAQ Module: We maintain a comprehensive FAQ database for common technical and logistical inquiries. Custom queries are handled by dedicated support personnel.

- Lead Time & Fulfillment: Standard lead time for bulk orders is 10-14 business days, subject to volume and customization. We utilize established logistics partners to ensure timely and secure delivery globally, providing real-time tracking.

- Warranty Commitments: Our products are guaranteed to meet the agreed-upon specifications upon delivery. Any discrepancies must be reported within 7 days of receipt, and a thorough investigation and resolution process will be initiated.

- Customer Support: Our dedicated B2B customer support team is available via phone (+86-139xxxxxxx) and email (sales@luhuawalnut.com) from Monday to Friday, 9:00 AM to 5:00 PM (GMT+8), providing technical assistance and order management.

- Certifications and Standards: We proudly adhere to ISO 22000, HACCP, and FDA guidelines, ensuring our products meet stringent international food safety and quality standards. Detailed audit reports and certificates are available upon request.

References

- USDA, Agricultural Marketing Service. (2018). U.S. Standards for Grades of Shelled Walnuts. Retrieved from www.ams.usda.gov

- Food and Drug Administration (FDA). (Current). Guidance for Industry: Action Levels for Aflatoxins in Human Food and Animal Feed. Retrieved from www.fda.gov

- International Organization for Standardization (ISO). (Various). ISO 22000 Food safety management systems – Requirements for any organization in the food chain; ISO 3960 Animal and vegetable fats and oils – Determination of peroxide value – Iodometric (visual) end-point determination. Retrieved from www.iso.org

- AOAC International. (Current). Official Methods of Analysis of AOAC International. Retrieved from www.aoac.org

- European Commission. (2006). Commission Regulation (EC) No 1881/2006 setting maximum levels for certain contaminants in foodstuffs. Retrieved from eur-lex.europa.eu

Hebei Luhua Import and Export Trade Co., Ltd.raisins is a large-scale walnut kernel processing factory, which has been focusing on the walnut kernel export industry since 1996 and established a foreign trade company in 2021.walnuts suppliers The factory covers an area of 50000 square meters, has a standardized production workshop, a BRC food safety certification enterprise, and has multiple professional production lines. xinjiang walnuts It can produce various specifications of walnut kernels and walnuts, with a daily output of up to 50 tons.organic cashews We can achieve faster delivery times and stable production, ensuring that you always have sufficient inventory to meet market demand.red dates|super blog