The Strategic Importance of Premium Shelled Walnuts in B2B Supply Chains

In the global food ingredient market, the demand for high-quality shelled walnuts is experiencing robust growth. As B2B decision-makers and food scientists, understanding the nuanced aspects of sourcing, processing, and application of premium walnut kernels is paramount. This comprehensive guide delves into the technical specifications, market dynamics, and operational advantages of integrating superior shelled walnuts into various industrial applications.

Industry Trends and Market Dynamics

The global walnut market is projected to grow significantly, driven by increasing consumer awareness of health benefits and rising demand from the bakery, confectionery, and health food sectors. Factors influencing this growth include a shift towards plant-based diets, the demand for natural and functional ingredients, and the convenience offered by processed kernels compared to unshelled walnuts. According to a report by Grand View Research, the global walnuts market size was valued at USD 7.2 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.1% from 2023 to 2030. This upward trajectory underscores the critical need for reliable, high-volume suppliers capable of meeting stringent quality requirements.

Key trends impacting the B2B walnut sector include:

- Emphasis on Origin and Traceability: Consumers and manufacturers increasingly demand transparency regarding the origin of their ingredients. Yunnan, China, is renowned for its specific walnut varietals, which are prized for their lighter color and distinct flavor profiles.

- Sustainability Practices: Sustainable farming and processing methods are becoming non-negotiable for ethical sourcing and brand reputation.

- Premiumization: A growing segment of the market seeks high-grade kernels, such as Extra Light Halves (ELH) and Light Halves (LH), for applications where aesthetics and sensory attributes are critical.

- Technological Advancements in Processing: Innovations in cracking, sorting, and grading technologies ensure higher yields of intact halves and superior quality consistency.

The Manufacturing Process of Premium Yunnan Walnut Kernels

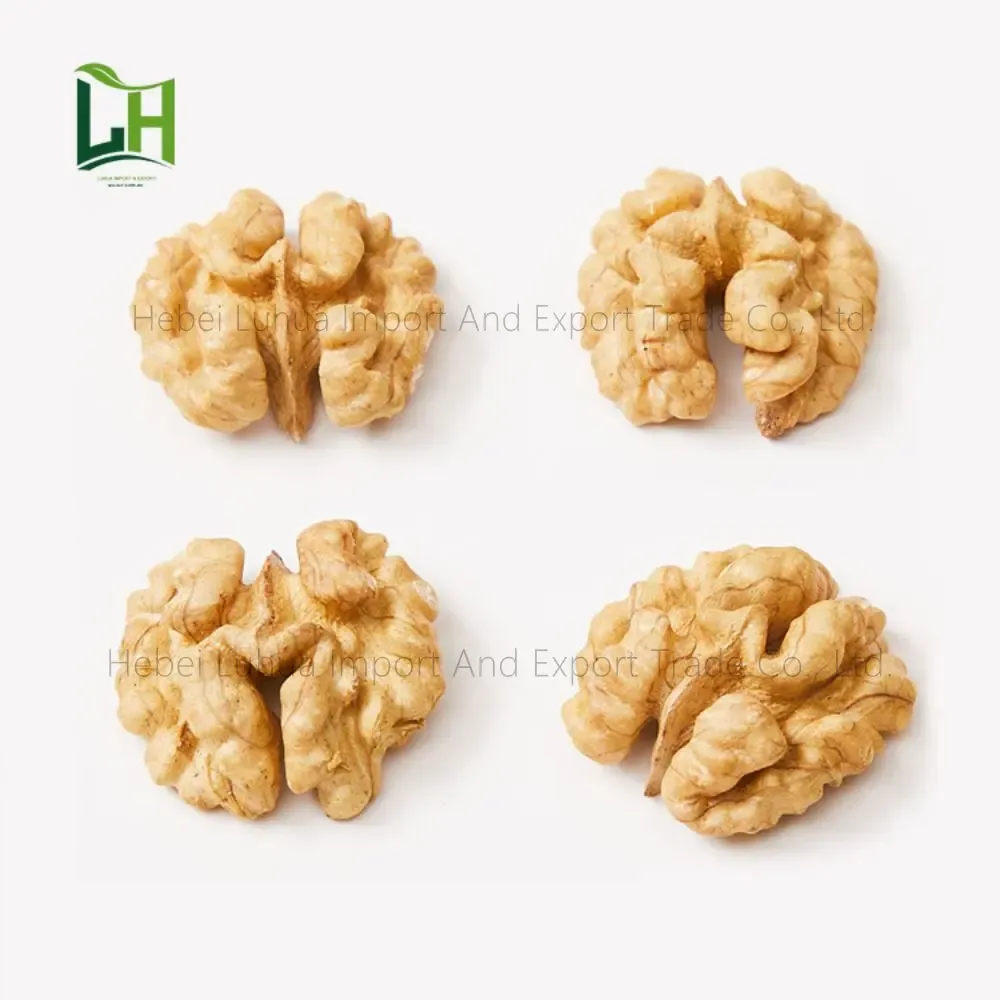

The production of high-quality shelled walnuts, particularly the Extra Light Halves (ELH) and Light Halves (LH) grades from Yunnan, involves a meticulous, multi-stage process designed to preserve the nutritional integrity, flavor, and visual appeal of the kernels. This process is crucial for producing a consistent “walnut 1 kg without shell” product that meets stringent B2B specifications.

Detailed Process Flow: From Harvest to Packaging

- Harvesting and Pre-cleaning: Walnuts are carefully harvested when fully mature, typically between September and October. They are then subjected to initial cleaning to remove leaves, twigs, and other field debris. This step is critical to prevent contamination at later stages.

- De-hulling: The green outer hull is mechanically removed, a process requiring precision to avoid damaging the inner shell. This step is usually performed shortly after harvest to prevent staining of the shell and kernel.

- Drying of Inshell Walnuts: The unshelled walnuts are carefully dried to a specific moisture content (typically 8-10%) to prevent mold growth and facilitate efficient cracking. Controlled drying ensures the kernel’s integrity and subsequent shelf life.

- Cracking: Specialized cracking machines are employed to gently open the shells while minimizing damage to the kernels. The goal is to maximize the yield of whole or large half kernels.

- Shell Separation: Advanced vibratory and air separation techniques are used to effectively separate the kernels from the shell fragments. This step is crucial for achieving high purity levels.

- Color and Size Sorting (Grading): Kernels are then sorted by color (e.g., Extra Light, Light, Light Amber) and size (Halves, Pieces). This often involves automated optical sorting machines that use sophisticated imaging technology to detect and remove discolored or imperfect kernels, ensuring consistent grading for products like Yunnan Walnut Kernels Extra Light Halves(ELH) and Light Halves(LH).

- Hand Sorting and Quality Inspection: Despite automation, a final stage of meticulous hand sorting by trained personnel is vital to remove any remaining foreign materials, broken pieces, or substandard kernels, ensuring the highest purity and quality standards.

- Drying of Kernels: The shelled walnuts undergo a final controlled drying process to achieve optimal moisture content (typically 4-6%) suitable for long-term storage and to prevent rancidity.

- Packaging: The finished kernels are carefully packed into vacuum-sealed bags, nitrogen-flushed packaging, or cartons, typically ranging from 10 kg to 25 kg, to protect them from oxidation, moisture, and pests, thus extending their shelf life.

Quality Assurance and Testing Standards

Throughout the process, stringent quality control measures are implemented to meet international standards such as ISO 22000, HACCP, and often FDA compliance for export. Key testing parameters include:

- Moisture Content: Critical for shelf stability, typically maintained below 6%.

- Aflatoxin Levels: Monitored rigorously to ensure compliance with food safety regulations.

- Peroxide Value and Free Fatty Acids (FFA): Indicators of rancidity; low levels denote freshness.

- Microbiological Analysis: Testing for pathogens like E. coli, Salmonella, and Listeria.

- Purity: Ensures minimal foreign matter and shell fragments.

Technical Specifications and Quality Parameters of Yunnan Walnut Kernels

For B2B procurement, precise technical specifications are non-negotiable. Yunnan Walnut Kernels, particularly the ELH and LH grades, are meticulously characterized by several critical parameters that dictate their suitability for various applications and ensure consistent product quality, whether you are buying a small sample or a walnut 1 kg without shell bulk package.

Product Specification Table: Yunnan Walnut Kernels (ELH & LH)

| Parameter | Yunnan ELH (Extra Light Halves) | Yunnan LH (Light Halves) | Testing Method/Standard |

|---|---|---|---|

| Color Classification | ≥80% Extra Light Halves | ≥80% Light Halves | USDA Grade Standards (Visual) |

| Halves Content | ≥80% Halves | ≥80% Halves | Mechanical Sieving/Visual Inspection |

| Broken Pieces (max) | ≤5% (smaller than halves) | ≤5% (smaller than halves) | Visual Inspection/Weight % |

| Moisture Content (max) | ≤6% | ≤6% | ISO 665:2000 (Oven Drying Method) |

| Foreign Matter (max) | ≤0.01% | ≤0.01% | Visual Inspection |

| Shell Fragments (max) | ≤0.01% | ≤0.01% | Visual Inspection |

| Free Fatty Acids (FFA) | ≤1.0% (as oleic acid) | ≤1.0% (as oleic acid) | AOCS Official Method Ca 5a-40 |

| Peroxide Value (PV) | ≤5 meq O₂/kg oil | ≤5 meq O₂/kg oil | AOCS Official Method Cd 8-53 |

| Microbiological Standards | Total Plate Count <10⁵ cfu/g, Yeast & Mold <10⁴ cfu/g, E.coli Absent | Total Plate Count <10⁵ cfu/g, Yeast & Mold <10⁴ cfu/g, E.coli Absent | AOAC / ISO Standard Methods |

Expertise Explained: These parameters are critical for determining the quality and shelf stability of shelled walnuts. For instance, low moisture content is essential to inhibit microbial growth and enzymatic activity that lead to spoilage. Low FFA and PV values indicate minimal lipid oxidation, ensuring the walnuts are fresh and free from rancid off-flavors. Adherence to these strict specifications is what differentiates a premium product suitable for demanding B2B applications.

Technical Advantages and Application Scenarios

The inherent qualities of premium Yunnan shelled walnuts, particularly the ELH and LH grades, offer distinct technical advantages that translate into superior product performance and consumer satisfaction across a myriad of B2B applications.

Technical Advantages

- Superior Aesthetic Appeal: The Extra Light Halves (ELH) and Light Halves (LH) grades boast a bright, uniform color, which is highly desirable in premium bakery goods, confectionery, and as a visual garnish. This consistency reduces product rejection rates due to appearance.

- Consistent Texture and Flavor Profile: Carefully processed kernels maintain their characteristic crunch and buttery, mild flavor. This consistency is crucial for product formulation and ensures a predictable sensory experience for the end-consumer.

- Extended Shelf Life: Optimized moisture content and advanced packaging (e.g., vacuum sealing, nitrogen flushing) significantly mitigate oxidation and microbial spoilage, providing a longer usable life for industrial applications, reducing waste, and improving inventory management.

- Nutritional Density: Walnuts are a rich source of Omega-3 fatty acids (alpha-linolenic acid – ALA), antioxidants, protein, and dietary fiber. Incorporating these shelled walnuts enhances the nutritional profile of finished products, aligning with health-conscious consumer trends.

- Reduced Contamination Risk: Rigorous sorting and cleaning processes minimize foreign matter and shell fragments, leading to a safer, higher-quality ingredient that reduces operational risks for food manufacturers.

Typical Application Scenarios and Target Industries

The versatility of high-quality walnut kernels makes them indispensable across a broad spectrum of industries:

- Bakery Industry: Widely used in breads, muffins, cakes, cookies, and pastries. The ELH and LH grades are particularly favored for their visual appeal in premium baked goods, where color retention after baking is critical.

- Confectionery: Essential in chocolates, pralines, nut clusters, and various candy bars. The texture and flavor provide an ideal counterpoint to sweet ingredients.

- Snack Industry: As standalone healthy snacks, in trail mixes, or incorporated into energy bars. The “walnut 1 kg without shell” format is ideal for bulk packaging for snack manufacturers.

- Dairy & Ice Cream: Used as inclusions in yogurts, ice creams, and frozen desserts, adding texture and nutritional value.

- Health Food & Nutraceuticals: Utilized in functional foods, dietary supplements, and breakfast cereals, leveraging their Omega-3 content and antioxidant properties.

- Salad & Savory Food Service: For garnishing salads, creating unique sauces, or as an ingredient in gourmet savory dishes.

These applications benefit directly from the consistent quality, purity, and aesthetic excellence provided by premium Yunnan shelled walnuts, ensuring that the end product meets the highest standards of taste and visual appeal.

Vendor Comparison and Customized Solutions

In the competitive B2B landscape, selecting the right supplier for shelled walnuts is a strategic decision that impacts product quality, supply chain reliability, and ultimately, profitability. Differentiating between vendors goes beyond mere price comparison; it involves evaluating quality control, certification, sourcing transparency, and the ability to provide tailored solutions.

Differentiating Premium Suppliers from Generic Providers

| Feature | Premium Supplier (e.g., Luhua Walnut) | Generic/Commodity Supplier |

|---|---|---|

| Sourcing Control | Direct sourcing from specific regions (e.g., Yunnan), ensuring varietal authenticity and quality control from farm to factory. | Often relies on brokers or multiple, less controlled sources, leading to inconsistent quality. |

| Quality Assurance & Certifications | Adherence to international standards (ISO 22000, HACCP, FDA-registered), comprehensive internal lab testing, third-party audits. | May have basic certifications, but often lacks rigorous internal QC and regular third-party verification. |

| Product Grading & Consistency | Strict grading for color, size (ELH, LH), and broken pieces, ensuring uniform batches suitable for precision manufacturing. | Variable grading, higher percentage of broken pieces or mixed colors, leading to rework or lower product quality. |

| Packaging Solutions | Advanced vacuum-sealing, nitrogen flushing, customized pack sizes (e.g., specific “walnut 1 kg without shell” options), designed for extended shelf life and specific B2B needs. | Standard bulk packaging with less emphasis on protective atmospheres, potentially compromising freshness. |

| Technical Support & Customization | Dedicated account management, ability to customize specifications (e.g., moisture, oil content, roast level), flexible delivery schedules. | Limited customization options, standardized products, less agile customer service. |

Customized Solutions

Recognizing that each B2B client has unique operational and product requirements, premium suppliers like Luhua Walnut offer tailored solutions. These include:

- Specific Grading and Sizing: Beyond standard ELH/LH, customized blends of halves and pieces, or specific piece sizes for particular machinery or product textures.

- Targeted Moisture Levels: Adjusting moisture content to optimize performance in specific manufacturing processes (e.g., baking, confectionery).

- Packaging Flexibility: Offering a range of bulk packaging from large totes to smaller 1kg bags, private labeling options, and specific packaging materials to suit client logistics and shelf-life requirements.

- Roasting/Treatment Options: Providing lightly roasted, raw, or other treated shelled walnuts based on application needs.

- Logistical Integration: Coordinated shipping schedules, optimized freight solutions, and inventory management support to ensure just-in-time delivery.

Application Case Studies: Realizing Value with Premium Shelled Walnuts

These hypothetical case studies illustrate how strategic partnership with a premium supplier of shelled walnuts, such as Luhua Walnut, can drive tangible benefits for B2B clients.

Case Study 1: Large-Scale Bakery Chain Enhancing Product Consistency

A national bakery chain specializing in artisanal breads and pastries faced challenges with inconsistent walnut kernel quality from their previous supplier. Batches often contained varying ratios of halves to pieces, and color inconsistencies affected the visual appeal of their premium products. This led to increased manual sorting, higher waste, and customer complaints about product appearance.

Solution: The bakery partnered with Luhua Walnut for a consistent supply of Yunnan Walnut Kernels Extra Light Halves (ELH). Luhua’s strict grading standards and advanced optical sorting technology ensured that each delivery met the precise specification of ≥80% ELH, with minimal broken pieces and uniform color. Luhua also provided specialized 10kg vacuum-sealed packs, which integrated seamlessly into the bakery’s production line.

Outcome: Within three months, the bakery reported a 15% reduction in ingredient waste due to improved consistency. Manual sorting labor was reduced by 20%, allowing staff to focus on other value-added tasks. Customer feedback on product appearance improved significantly, reinforcing the brand’s premium image. The stable supply and consistent quality also allowed for more predictable production scheduling.

Case Study 2: Health Food Manufacturer Optimizing Nutritional Value and Shelf Life

A health food company producing Omega-3 rich snack bars and cereals required shelled walnuts with guaranteed nutritional integrity and an extended shelf life to meet their product specifications and distribution network. Their previous supplier’s kernels exhibited higher-than-desired peroxide values, leading to concerns about premature rancidity and reduced nutritional efficacy.

Solution: Luhua Walnut provided Yunnan Walnut Kernels (LH grade) with documented low peroxide values (PV ≤ 5 meq O₂/kg oil) and free fatty acids (FFA ≤ 1.0%), validated by third-party laboratory reports. They also implemented nitrogen-flushed, multi-layer foil packaging for 25kg bulk orders to further protect the kernels from oxygen exposure. Furthermore, Luhua maintained a transparent supply chain, offering traceability from specific Yunnan farms.

Outcome: The health food manufacturer successfully extended the shelf life of their finished products by an additional two months, reducing product returns and improving inventory rotation. Consumer testing confirmed the absence of off-flavors, reinforcing the product’s natural and healthy positioning. The guaranteed nutritional profile allowed the company to confidently make health claims on their packaging, supported by authoritative supplier data.

Trustworthiness: FAQs, Fulfillment, Warranty & Support

Building trust with B2B partners requires transparency, reliable logistics, and robust support systems. Here, we address common inquiries and outline our commitment to client satisfaction for shelled walnuts.

Frequently Asked Questions (FAQ)

- Q: What is the recommended storage for shelled walnuts?

A: To maintain optimum freshness and prevent rancidity, store shelled walnuts in a cool (0-4°C / 32-40°F), dry place, ideally in airtight or vacuum-sealed packaging. Refrigeration or freezing is recommended for extended storage. - Q: What is the typical shelf life of your Yunnan Walnut Kernels?

A: When stored correctly in sealed packaging, our Yunnan Walnut Kernels (ELH/LH) have a shelf life of 12-18 months from the date of packing. - Q: Are your walnuts free from common allergens?

A: Walnuts are tree nuts, which are a common allergen. Our processing facilities handle tree nuts. We adhere to strict allergen control protocols to prevent cross-contamination, but advise clients to declare walnuts as an allergen. - Q: Can you provide organic certified shelled walnuts?

A: Yes, we offer organically certified options for our Yunnan Walnut Kernels, compliant with USDA Organic and EU Organic standards. Please specify your organic certification requirements during inquiry. - Q: How do you ensure your walnuts are free from pesticides and heavy metals?

A: We work directly with growers who adhere to strict agricultural practices. Our products undergo regular testing for pesticide residues and heavy metals by accredited third-party laboratories to ensure compliance with international food safety limits.

Lead Time and Fulfillment

Our standard lead time for most bulk orders of Yunnan Walnut Kernels is 15-20 business days from order confirmation, depending on volume and specific customization requirements. We maintain robust inventory levels and efficient logistics partnerships to ensure timely and reliable delivery worldwide. Expedited shipping options are available upon request and subject to current capacity.

Warranty Commitments

We stand by the superior quality of our shelled walnuts. All products are guaranteed to meet the agreed-upon technical specifications and quality standards at the time of delivery. In the rare event of a quality deviation, we offer a comprehensive warranty, including product replacement or credit, provided issues are reported within a specified period (typically 7-10 days post-delivery) and accompanied by appropriate documentation (e.g., batch number, storage conditions, photographic evidence).

Customer Support and After-Sales Service

Our dedicated B2B account managers provide personalized support from initial inquiry through order fulfillment and after-sales service. We offer technical assistance regarding product application, storage recommendations, and quality compliance. For any inquiries, technical support, or to discuss custom requirements, clients can reach us via our website contact form, dedicated email, or direct phone line during business hours. Our commitment is to foster long-term partnerships built on trust and mutual success.

Conclusion

The strategic selection of premium shelled walnuts is a critical determinant of product quality, operational efficiency, and market competitiveness for B2B enterprises. By focusing on superior origins like Yunnan, adhering to rigorous processing standards, and partnering with vendors committed to quality and customization, businesses can unlock significant value. The detailed technical specifications, robust quality control, and comprehensive support offered by specialized suppliers like Luhua Walnut ensure a reliable, high-performing ingredient that meets the evolving demands of the global food industry.

Authoritative References

- Grand View Research. (2023). Walnuts Market Size, Share & Trends Analysis Report. Retrieved from https://www.grandviewresearch.com/industry-analysis/walnuts-market

- USDA Agricultural Marketing Service. (2022). Grade Standards for Walnuts in the Shell and Shelled Walnuts. Retrieved from https://www.ams.usda.gov/grades-standards/walnuts-standards

- Food and Agriculture Organization of the United Nations (FAO). (2021). The Walnut Industry: Production, Trade, and Consumption. Retrieved from https://www.fao.org/faostat/en/#data/QC

- International Organization for Standardization (ISO). (2018). ISO 22000:2018 Food safety management systems – Requirements for any organization in the food chain.

- AOCS (American Oil Chemists’ Society) Official Methods and Recommended Practices. (2017).

Hebei Luhua Import and Export Trade Co., Ltd.raisins is a large-scale walnut kernel processing factory, which has been focusing on the walnut kernel export industry since 1996 and established a foreign trade company in 2021.walnuts suppliers The factory covers an area of 50000 square meters, has a standardized production workshop, a BRC food safety certification enterprise, and has multiple professional production lines. xinjiang walnuts It can produce various specifications of walnut kernels and walnuts, with a daily output of up to 50 tons.organic cashews We can achieve faster delivery times and stable production, ensuring that you always have sufficient inventory to meet market demand.red dates|super blog