Navigating the Global Walnut Market: Innovations in Stripped Walnut Production

The global walnut market is undergoing a significant transformation, driven by increasing consumer demand for convenient, high-quality, and nutrient-dense food products. Central to this evolution is the advancements in processing technology, particularly in how we peel walnut kernels efficiently while preserving their inherent nutritional integrity and sensory profile. This process, often referred to as walnut stripping or shelling, is not merely about removing the outer shell but involves a sophisticated series of steps designed to deliver a premium product to diverse industries. The shift towards automation and precision in shelling, coupled with optimized drying techniques, has become paramount for manufacturers aiming to meet stringent international quality standards and satisfy the growing appetite for wholesome ingredients in segments ranging from confectionery to health supplements. Understanding the nuances of this complex supply chain, from raw material sourcing to final product delivery, is critical for B2B buyers seeking reliable, high-volume supplies of meticulously processed walnuts. The continued investment in research and development within the nut processing sector is yielding innovative solutions that enhance yield, reduce waste, and improve the overall shelf life of peeled walnuts, thereby significantly impacting their market availability and the stability of peeled walnuts price fluctuations. This introductory overview sets the stage for a deeper dive into the specific technological advancements and quality assurances that define superior stripped walnut kernels in today’s competitive landscape.

Industry trends indicate a strong move towards traceability and sustainability within the agricultural supply chain, and the walnut sector is no exception. Consumers and industrial buyers alike are increasingly demanding transparency regarding the origin, processing methods, and environmental impact of the products they procure. This pressure is driving processors to adopt more eco-friendly technologies, minimize water usage, and ensure ethical labor practices throughout their operations. Furthermore, the burgeoning demand for organic and non-GMO products has opened new market segments for specialized walnut suppliers. These trends collectively underscore the importance of not just efficient processing but also adherence to global best practices in food safety and environmental stewardship. For instance, the market for pre-portioned, ready-to-use peeled walnuts has seen remarkable growth, fueled by convenience-oriented lifestyles and the expansion of the food service sector. Manufacturers who can consistently supply high-quality, compliant products are well-positioned to capitalize on these opportunities, establishing long-term partnerships with clients who value reliability and integrity. The technological innovations in drying, sorting, and packaging play a pivotal role in extending the freshness and utility of the finished product, making them suitable for diverse applications requiring specific moisture levels and kernel integrity, which directly influences their market value and perceived quality among buyers globally.

The Advanced Process of Producing Chinese Professional Stripped and Drying Pieces Walnut Kernel

The production of high-quality Chinese professional stripped and drying pieces walnut kernel involves a meticulously engineered process that goes far beyond simple cracking. It begins with the careful selection of raw walnuts, primarily sourced from regions renowned for their superior varieties, ensuring optimal size, freshness, and absence of defects. Once harvested, the walnuts undergo an initial cleaning phase to remove dirt and debris, followed by precise sizing to ensure uniform processing. The crucial step of shelling, or how to peel walnut, employs advanced mechanical cracking machines designed to minimize kernel breakage while efficiently separating the kernel from the shell. Unlike traditional methods that can damage the delicate kernel, modern machinery utilizes controlled pressure and vibration, often incorporating optical sorting technologies to identify and remove shell fragments automatically. Post-shelling, the kernels are meticulously hand-sorted to eliminate any remaining shell pieces or imperfect kernels, a testament to the blend of technological precision and skilled manual labor that defines premium production. This rigorous selection ensures only the finest, intact kernels proceed to the next critical stage.

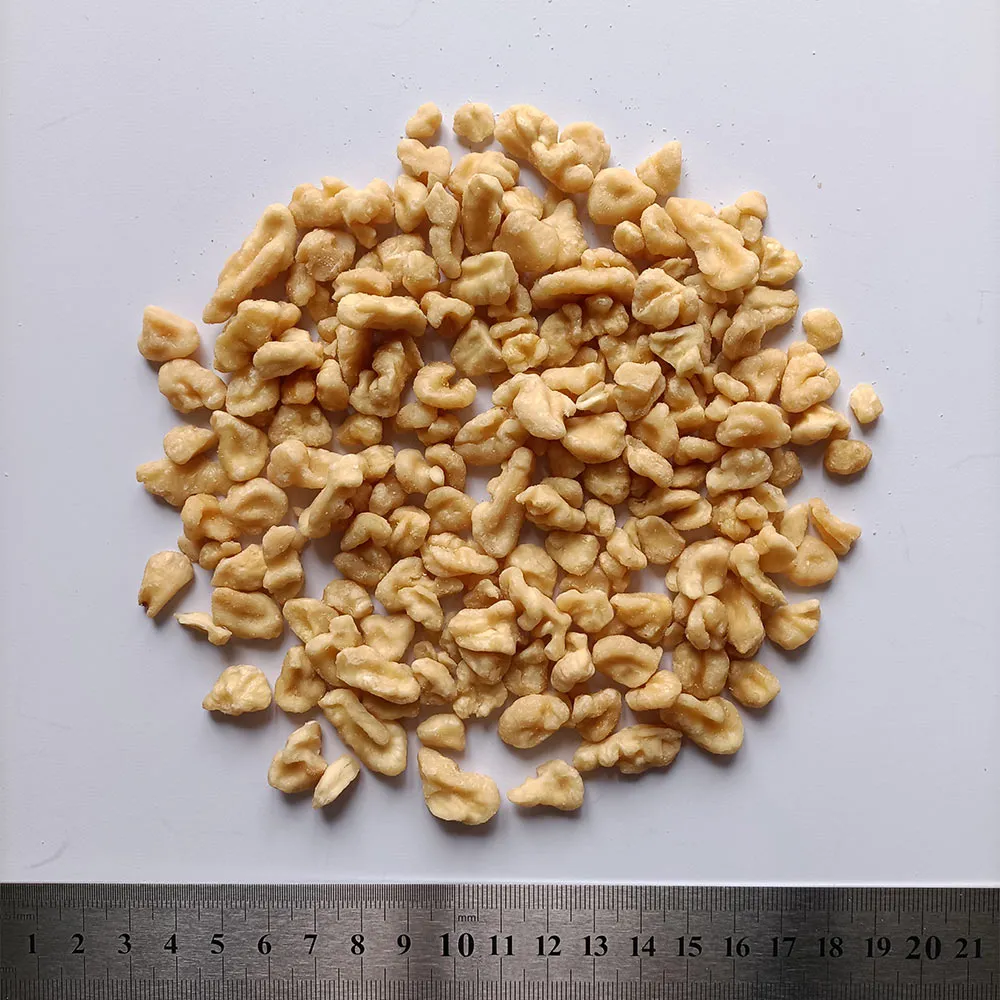

Following the shelling and initial sorting, the walnuts undergo a specialized drying process. This phase is critical for achieving the optimal moisture content, which is typically around 4-6%, essential for preserving freshness, preventing microbial growth, and extending shelf life. Modern drying techniques often involve controlled low-temperature air drying in specialized chambers, ensuring uniform moisture reduction without compromising the kernel’s texture, flavor, or nutritional value. This contrasts sharply with high-heat methods that can lead to rancidity or a burnt taste. Post-drying, the walnuts pass through sophisticated color sorters and metal detectors, adhering to stringent food safety standards such as HACCP (Hazard Analysis and Critical Control Points) and ISO 22000 certifications, which are vital for international trade and consumer trust. These automated systems identify and remove any discolored kernels or foreign materials, ensuring a consistently high-quality output. The final stage involves precise sizing and grading of the dried kernel pieces based on established industry standards – halves, quarters, or smaller pieces – to meet specific client requirements for various culinary and industrial applications. This comprehensive manufacturing process, from raw material to packaged product, adheres to global food safety protocols and sustainability practices, ensuring that the Chinese professional stripped and drying pieces walnut kernel consistently meets and exceeds the expectations of the most discerning B2B clients globally, thus justifying their premium quality and competitive peeled walnuts price.

Technical Specifications and Unmatched Advantages of Our Peeled Walnuts

Our Chinese professional stripped and drying pieces walnut kernel stands out due to its adherence to rigorous technical specifications and the significant advantages it offers to industrial buyers. The meticulous process to peel walnut kernels ensures a product with superior attributes, particularly concerning purity, moisture content, and overall integrity. We guarantee a minimum purity level of 99.9%, meaning virtually no shell fragments, foreign materials, or imperfect kernels are present, which is crucial for applications where food safety and product consistency are paramount. This high purity directly translates into reduced waste for our clients and increased efficiency in their production lines. Furthermore, our precision drying process maintains an optimal moisture content range of 4-6%, a critical parameter for preventing mold development, preserving the natural oils, and extending the product’s shelf life significantly. This controlled moisture level ensures that the walnuts retain their crisp texture and characteristic nutty flavor, preventing issues like rancidity that can compromise the final product quality in confectionery, bakery, or snack formulations.

| Parameter | Specification | Industry Standard (Typical) | Benefit to Customer |

|---|---|---|---|

| Moisture Content | 4.0% – 6.0% | Typically 6-8% | Extended shelf life, reduced microbial risk, preserved freshness. |

| Purity (Foreign Material) | > 99.9% | Typically 99.5-99.8% | Minimized waste, enhanced food safety, higher product yield. |

| Kernel Integrity (Halves/Pieces) | Specific to grade (e.g., Light Halves: >80% halves) | Varies by grade | Consistent appearance, suitability for specific applications (e.g., whole halves for garnish). |

| Peroxide Value (PV) | < 5 meq O2/kg | Typically 5-10 meq O2/kg | Indication of minimal oxidation, ensures fresh flavor, extended storage. |

| Free Fatty Acids (FFA) | < 1.0% | Typically 1.0-2.0% | Reflects low hydrolysis, contributes to stable flavor and reduced rancidity. |

Beyond these quantifiable parameters, the advantages extend to consistency in supply and customized solutions. Our streamlined production process, from sourcing to packaging, enables us to provide a stable supply of peeled walnuts, crucial for manufacturers operating on tight production schedules. The ability to supply various grades and sizes – from halves and quarters to specific smaller pieces – allows for tailored solutions for diverse industrial needs, whether for snack packs, bakery inclusions, or ingredient formulations. Our commitment to quality is underpinned by adherence to internationally recognized food safety management systems such as FSSC 22000 and BRCGS (Brand Reputation Compliance Global Standard), ensuring every batch meets the highest standards of safety and quality control. This robust quality assurance framework provides our clients with unparalleled peace of mind, knowing they are receiving a product that is not only premium in quality but also compliant with global regulatory requirements. Furthermore, our efficient processing methods result in minimal product degradation, translating to superior texture and flavor profiles in the end-use applications, which significantly enhances the value proposition for our discerning B2B partners who prioritize both performance and economic efficiency in their procurement of peeled walnuts.

Versatile Applications and Real-World Impact of Our Peeled Walnuts

The versatility of high-quality peeled walnuts makes them an indispensable ingredient across a multitude of industries, driven by their nutritional profile, distinctive flavor, and textural attributes. In the food manufacturing sector, our Chinese professional stripped and drying pieces walnut kernel finds extensive use in confectionery, enhancing chocolates, candies, and pralines with a rich, nutty crunch. Bakery industries utilize them in breads, muffins, cakes, and cookies, where their consistent quality and optimal moisture content ensure superior dough integration and extended freshness of baked goods. The snack food industry is another significant consumer, with walnuts being a popular ingredient in trail mixes, health bars, and roasted nut blends, appealing to health-conscious consumers. Beyond traditional applications, the increasing demand for plant-based proteins and nutrient-dense ingredients has propelled walnuts into new market segments, including dairy alternatives, meat substitutes, and functional foods. Our product’s consistent sizing and minimal breakage, achieved through our advanced process to peel walnut, make them ideal for automated production lines, reducing operational complexities and increasing efficiency for large-scale manufacturers. This broad applicability, coupled with our rigorous quality control, positions our peeled walnuts as a preferred choice for diverse industrial needs, contributing significantly to product innovation and consumer satisfaction across various food categories.

Case studies further exemplify the real-world impact and reliability of our peeled walnuts. A leading European snack food producer recently reported a 15% increase in production efficiency and a noticeable reduction in ingredient waste after switching to our product, attributing these improvements to the consistent purity and uniform sizing of our stripped walnut kernels. This allowed them to optimize their automated packaging lines and maintain tighter control over portioning, directly impacting their profitability. Similarly, a major US-based bakery chain highlighted the superior freshness and extended shelf life of their walnut-infused bread lines, directly correlating it with the controlled moisture content and low peroxide values of our supplied walnuts, which significantly reduced spoilage rates during distribution. In the health and wellness sector, a nutraceutical company developing plant-based protein powders integrated our finely processed walnut pieces, citing their consistent nutrient profile and low microbial count as critical factors in meeting their stringent formulation requirements and regulatory compliance for their products targeting the growing market for functional ingredients. These diverse application scenarios and positive client testimonials underscore our product’s ability to not only meet but exceed demanding industrial specifications, providing a reliable and high-value ingredient that contributes directly to our clients’ success and innovative product development across global markets.

Manufacturer Comparison and Tailored Solutions for Stripped Walnuts

When selecting a supplier for high-volume peeled walnuts, B2B buyers often face a complex decision, weighing factors such as price, quality consistency, and supply reliability. While many manufacturers can supply walnuts, our distinct advantage lies in our specialized expertise in processing Chinese walnuts and our unwavering commitment to advanced technology and stringent quality control. Unlike some competitors who may rely on less refined processing methods or outsource critical stages, we maintain comprehensive control over the entire production chain, from sourcing premium raw materials to final packaging. This vertical integration allows us to ensure unparalleled consistency in purity, moisture content, and kernel integrity, which directly impacts the performance of our walnuts in industrial applications. For instance, our advanced optical sorting systems and metal detection capabilities significantly surpass industry averages in minimizing foreign material contamination, a critical concern for food manufacturers. Furthermore, our strategic location in key walnut-producing regions enables us to secure the freshest raw materials, minimizing transit times and preserving the intrinsic quality of the walnuts before they undergo the careful process to peel walnut kernels. This commitment to in-house expertise and quality control sets us apart from competitors who might offer lower peeled walnuts price points but often compromise on purity or consistency, leading to higher hidden costs for the buyer in terms of waste and production downtime.

Beyond standardized products, we specialize in developing bespoke solutions tailored to the unique requirements of our industrial clients. Recognizing that each industry and application may have distinct needs, we offer customizable options ranging from specific kernel sizing (e.g., precise cuts for cereal topping vs. larger halves for confectionery garnish) and moisture content adjustments to specialized packaging formats, including bulk bags, vacuum-sealed pouches, or modified atmosphere packaging to extend shelf life for particular distribution channels. Our technical team works closely with clients’ R&D departments to understand their exact specifications and operational challenges, providing expert guidance and samples for testing to ensure optimal integration into their product lines. This collaborative approach allows us to not only meet but often exceed client expectations, fostering long-term partnerships built on mutual trust and shared success. For example, a client requiring specific “light amber” color grades for a premium bakery product received a customized batch sorted with exceptional precision, ensuring aesthetic consistency across their entire product line. This level of customization and technical support distinguishes us from generic suppliers and highlights our commitment to being a strategic partner rather than just a vendor, providing superior value that extends far beyond the initial peeled walnuts price. Our dedication to innovation ensures that we remain at the forefront of the industry, capable of adapting to evolving market demands and delivering solutions that provide a tangible competitive edge for our clients.

Ensuring Trust, Authority, and Exceptional Support for Our Peeled Walnuts

Establishing and maintaining trust is paramount in the B2B food ingredients sector, especially for a sensitive product like peeled walnuts. Our company’s authority in the industry is built on a foundation of rigorous certifications, extensive service tenure, and unwavering commitment to quality assurance. We operate under internationally recognized certifications such as ISO 22000 for Food Safety Management Systems, HACCP (Hazard Analysis and Critical Control Points) principles, and often hold specific organic or non-GMO certifications as required by diverse markets. These accreditations are not merely symbolic; they represent a deep operational integration of global best practices in food hygiene, processing, and traceability, ensuring that every batch of Chinese professional stripped and drying pieces walnut kernel meets the highest international benchmarks. Our decades of experience in the walnut industry, coupled with strong relationships with growers and continuous investment in advanced processing technologies, underscore our authoritative position. We also provide comprehensive Certificates of Analysis (CoA) with every shipment, detailing parameters such as moisture content, purity, microbial load, and peroxide value, offering full transparency and verifiable quality data to our clients. This meticulous documentation and adherence to global standards reinforce our credibility and provide our partners with complete confidence in our product and processes, ensuring they receive consistently high-quality peeled walnuts at a competitive price, backed by verifiable data.

Beyond certifications, our commitment to trustworthiness extends to our robust support infrastructure and clear operational policies. We understand the critical importance of timely delivery and supply chain reliability for our B2B partners. Our typical delivery cycle is meticulously managed to ensure efficient logistics from our facilities to global destinations, often ranging from 7-14 days for international shipments depending on destination and volume, with clear communication on lead times. Every shipment is backed by a comprehensive quality assurance policy, guaranteeing that products meet agreed-upon specifications upon arrival. Should any discrepancies arise, our dedicated customer support team is available to address concerns promptly and professionally, committed to swift resolution and client satisfaction. We offer flexible warranty agreements that cover product quality and consistency, reflecting our confidence in our processing capabilities and product integrity. Our commitment to client support is proactive, offering technical consultation and market insights to help our partners optimize their usage of our stripped walnuts and navigate market trends, ensuring a collaborative and beneficial relationship. This holistic approach to service, encompassing everything from initial inquiry to post-delivery support and a transparent peeled walnuts price structure, solidifies our position as a trusted and reliable partner in the global market for high-quality walnut kernels, ensuring the continued success of businesses that rely on our superior products.

Frequently Asked Questions (FAQ) about Our Peeled Walnuts

Q1: What is the typical shelf life of your Chinese professional stripped and drying pieces walnut kernel?

A1: When stored correctly in cool, dry conditions (ideally below 10°C / 50°F and relative humidity below 60%), our peeled walnuts typically maintain optimal quality for 12-18 months from the production date. Our low moisture content (4-6%) and low peroxide values are critical factors in achieving this extended shelf life, significantly reducing the risk of rancidity and microbial spoilage. For industrial buyers, understanding how to effectively peel walnut and store them to maximize shelf life is crucial for inventory management.

Q2: How do you ensure the purity and absence of shell fragments in your peeled walnuts?

A2: Our stringent process involves multiple stages of cleaning, sorting, and inspection. After mechanical shelling, kernels undergo initial hand-sorting. This is followed by advanced optical sorting machines that utilize high-resolution cameras to detect and remove even minute shell fragments or foreign materials based on color and shape differences. Finally, metal detectors ensure the absence of any metallic contaminants. This multi-layered approach guarantees a purity level exceeding 99.9%, critical for industrial applications where foreign material contamination is unacceptable and could impact the final peeled walnuts price.

Q3: Can you accommodate specific sizing or color grade requirements for bulk orders?

A3: Absolutely. We pride ourselves on offering customized solutions. We can supply peeled walnuts in various sizes, including halves, quarters, pieces, or specific granulations, to suit diverse industrial applications like bakery inclusions, snack mixes, or confectionary fillings. We also offer sorting by color grade (e.g., Light, Light Amber, Amber) to match specific aesthetic and functional requirements for premium products. Our technical sales team works closely with clients to define precise specifications and ensure the delivered product aligns perfectly with their needs, optimizing their overall peeled walnuts price efficiency.

Q4: What food safety certifications do your facilities and products hold?

A4: Our processing facilities adhere to the highest international food safety standards. We are certified under ISO 22000 for Food Safety Management Systems and implement HACCP principles rigorously throughout our production process. Depending on market requirements, we also hold certifications like FSSC 22000 and BRCGS (Brand Reputation Compliance Global Standard), and can provide organic or non-GMO certifications upon request. These certifications are independently audited annually, reflecting our unwavering commitment to producing safe, high-quality peeled walnuts.

Q5: How do your drying methods preserve the nutritional value of the walnuts?

A5: We utilize advanced low-temperature drying techniques that gently reduce moisture content without exposing the walnuts to excessive heat. This method is crucial for preserving the delicate polyunsaturated fats (omega-3 and omega-6 fatty acids), vitamins, minerals, and antioxidants that make walnuts so nutritious. Unlike conventional high-heat drying, our process prevents the degradation of these sensitive compounds, ensuring that our Chinese professional stripped and drying pieces walnut kernel retains its full nutritional integrity and superior flavor profile, which contributes to its value proposition.

Conclusion: Partnering for Excellence in Peeled Walnut Supply

The selection of a reliable supplier for high-quality peeled walnuts is a strategic decision for any B2B buyer in the food industry. Our commitment to excellence, from meticulous raw material selection and advanced processing techniques to stringent quality control and bespoke client solutions, positions us as a leading provider of Chinese professional stripped and drying pieces walnut kernel. We understand that consistency in product quality, adherence to global food safety standards, and reliable supply chain logistics are not merely advantages but necessities for our industrial partners. By focusing on superior purity, optimal moisture content, and robust quality certifications, we ensure that our walnuts not only meet but exceed the demanding specifications of diverse applications, contributing directly to the success and innovation of our clients’ end products. Our expertise in how to precisely peel walnut kernels, coupled with our dedication to customer service and transparent communication regarding peeled walnuts price and supply, establishes a foundation for enduring and mutually beneficial partnerships. We invite B2B decision-makers and technical procurement teams to experience the difference that genuine quality and a dedicated partnership can make in their supply chain, ensuring a reliable source of premium walnut kernels for their ongoing production needs.

Academic References:

- Food and Agriculture Organization of the United Nations (FAO). (2023). Global Nuts and Dried Fruits Production Statistics.

- International Nut & Dried Fruit Council (INC). (2022). World Edible Nuts Statistics.

- Codex Alimentarius Commission. (2021). General Standard for Edible Nuts.

- Journal of Food Science and Technology. (Various Issues). Research on Post-Harvest Processing and Shelf Life of Walnuts.

Hebei Luhua Import and Export Trade Co., Ltd.raisins is a large-scale walnut kernel processing factory, which has been focusing on the walnut kernel export industry since 1996 and established a foreign trade company in 2021.walnuts suppliers The factory covers an area of 50000 square meters, has a standardized production workshop, a BRC food safety certification enterprise, and has multiple professional production lines. xinjiang walnuts It can produce various specifications of walnut kernels and walnuts, with a daily output of up to 50 tons.organic cashews We can achieve faster delivery times and stable production, ensuring that you always have sufficient inventory to meet market demand.red dates|super blog